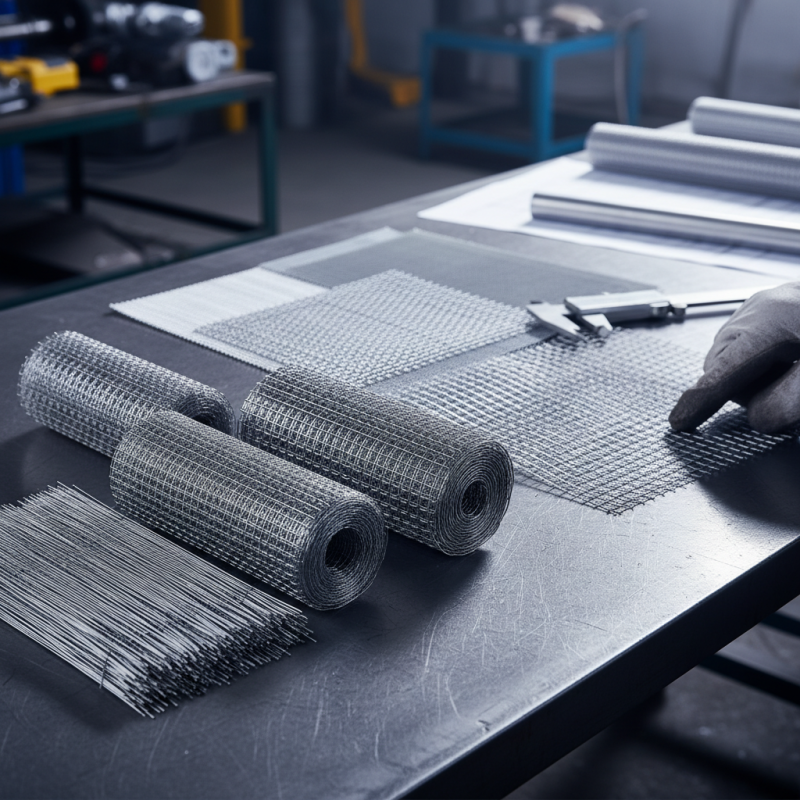

Essential Tips for Choosing Stainless Steel Wire Mesh?

When considering stainless steel wire mesh, several factors demand attention. The global market size for wire mesh is projected to reach approximately USD 7.4 billion by 2027, with stainless steel products commanding a significant share. This growth stems from their widespread use in various industries, including construction, food processing, and automotive. Stainless steel wire mesh offers durability, corrosion resistance, and flexibility, making it a favorite among manufacturers.

Quality is paramount when choosing stainless steel wire mesh. There are numerous options available, often leading to confusion among buyers. Factors like wire thickness, opening size, and material grade play critical roles in performance. For instance, Type 304 stainless steel is popular due to its versatility and good mechanical properties. However, some might overlook the importance of selecting the right mesh for their specific applications.

Pricing can vary considerably based on quality and sourcing. While cheaper options may tempt buyers, they often compromise on durability. Customers need to reflect on whether short-term savings are worth the potential for higher replacement costs. Selecting the right stainless steel wire mesh requires careful analysis, considering both immediate needs and future applications.

Understanding the Different Grades of Stainless Steel Wire Mesh

Choosing the right stainless steel wire mesh involves understanding the different grades available. Stainless steel comes in various grades, with 304 and 316 being the most common. These grades differ in chemical composition, which affects their corrosion resistance and mechanical properties. According to industry reports, grade 304 offers good corrosion resistance for most environments. However, exposure to saline conditions may lead to pitting corrosion.

On the other hand, grade 316 has superior resistance to chlorides. This makes it ideal for marine applications. The increased molybdenum content in 316 also helps to prevent rust in humid environments. Data suggests that 316 mesh can last up to 50% longer than 304 in coastal regions. This difference can be crucial for long-term projects.

However, choosing a higher grade means a higher cost. Often, users may compromise between price and durability. Some might overlook grade specifications in favor of immediate needs. Understanding these nuances is vital for achieving the desired functionality and longevity. The decision should reflect the specific application rather than just the cost involved.

Factors to Consider When Selecting Stainless Steel Wire Mesh

When selecting stainless steel wire mesh, several important factors come into play. The mesh's gauge impacts its strength and flexibility. Thicker wires provide durability, while thinner options offer better filtration. It's essential to assess your specific needs to make the right choice.

Consider the opening size of the mesh. Smaller openings filter finer materials, while larger openings allow for better airflow. Think about what materials you'll be working with and how the mesh will perform in that context. Additionally, realize that the wire's finish affects its corrosion resistance. Some finishes may not withstand harsh environments.

Here are a few tips: Always consult with professionals if you're unsure. Evaluate your budget against the durability you need. If a mesh appears attractive but feels flimsy, it might not be the best choice. Remember, price isn't always a reflection of quality. You want a balance between cost and performance that suits your application.

Applications of Stainless Steel Wire Mesh in Various Industries

Stainless steel wire mesh has diverse applications across multiple industries. In food processing, it is frequently used for sieving and filtering. The mesh ensures hygiene and prevents contamination. This is crucial, as food safety standards demand rigorous cleanliness. In the construction sector, it acts as reinforcement and a safety barrier. Builders rely on its strength to enhance concrete structures. However, corrosion can be an issue over time. Regular maintenance is essential to maximize its lifespan.

In the medical field, stainless steel wire mesh is used in surgical instruments and devices. Its biocompatibility makes it suitable for various applications. Yet, improper handling during manufacturing can lead to defects. Such flaws might affect the performance and safety of medical devices. Similarly, in the automotive industry, this mesh serves as a filter in exhaust systems. It helps reduce emissions, contributing to environmental sustainability. However, choosing the wrong type of mesh can compromise efficiency. Evaluating the mesh specifications is vital for optimal performance.

Essential Tips for Choosing Stainless Steel Wire Mesh

| Dimension | Wire Diameter (mm) | Aperture Size (mm) | Material Grade | Applications |

|---|---|---|---|---|

| 1/4" x 1/4" | 0.5 | 6.35 | 304 | Food Processing, Filtration |

| 1/2" x 1/2" | 0.6 | 12.7 | 316 | Pharmaceutical, Chemical |

| 1" x 1" | 0.8 | 25.4 | 304 | Construction, Mining |

| 2" x 2" | 1.0 | 50.8 | 316 | Animal Cages, Incubators |

| 3/4" x 3/4" | 0.7 | 19.05 | 304 | Security Screens, Ventilation |

Maintenance Tips for Longevity of Stainless Steel Wire Mesh

Stainless steel wire mesh is a popular choice for various applications. However, its longevity greatly depends on proper maintenance. Regular cleaning is vital. Dirt and debris can accumulate, leading to corrosion. According to a recent industry report, up to 30% of wire mesh failures stem from inadequate upkeep.

For effective maintenance, use mild detergents and soft brushes. Harsh chemicals can damage the protective layer of stainless steel. Rinsing thoroughly prevents residue build-up. Additionally, inspect the mesh periodically for signs of wear. Minor damages, if left unattended, can escalate into severe issues. Studies indicate that proactive maintenance can extend the lifespan of wire mesh by 40%.

Environmental factors also play a role. For instance, exposure to saltwater environments significantly accelerates corrosion. In such cases, more frequent maintenance may be necessary. It may be valuable to consider using a protective coating. This can enhance durability but may require additional care. Ultimately, understanding the specific conditions your wire mesh endures is crucial for its longevity.

Essential Tips for Choosing Stainless Steel Wire Mesh

This chart illustrates the common factors to consider when choosing stainless steel wire mesh and the importance of regular maintenance for longevity.

Cost Considerations When Choosing Stainless Steel Wire Mesh

When selecting stainless steel wire mesh, cost plays a crucial role. Understanding the price range helps in making informed decisions. Generally, prices vary based on the grade of stainless steel and the size of the mesh. Some may find cheaper options appealing, but low-quality materials might lead to higher costs later. Durability matters.

Installation also influences overall expenses. Complex setups require skilled labor, which adds to the budget. Sometimes, overlooked accessories like frames and anchors can increase costs. Considering the long-term view is essential. Choosing inferior mesh to save money can backfire.

Maintenance is another factor. Stainless steel is known for its resistance, yet it needs the right care. Neglect can result in rust or corrosion, prompting unexpected replacement costs. Previous buyers have realized this too late. Sometimes, it's not just about the upfront price; it’s about value over time. Making a wise choice demands thoughtful reflection.

Skip to content

Skip to content