What is Custom Glass Bottle Screw Lid and Its Benefits?

Custom Glass Bottle Screw Lid offers a unique solution for various packaging needs. These lids are designed to fit securely on glass bottles, ensuring product safety and longevity. They are durable and versatile, making them ideal for numerous applications.

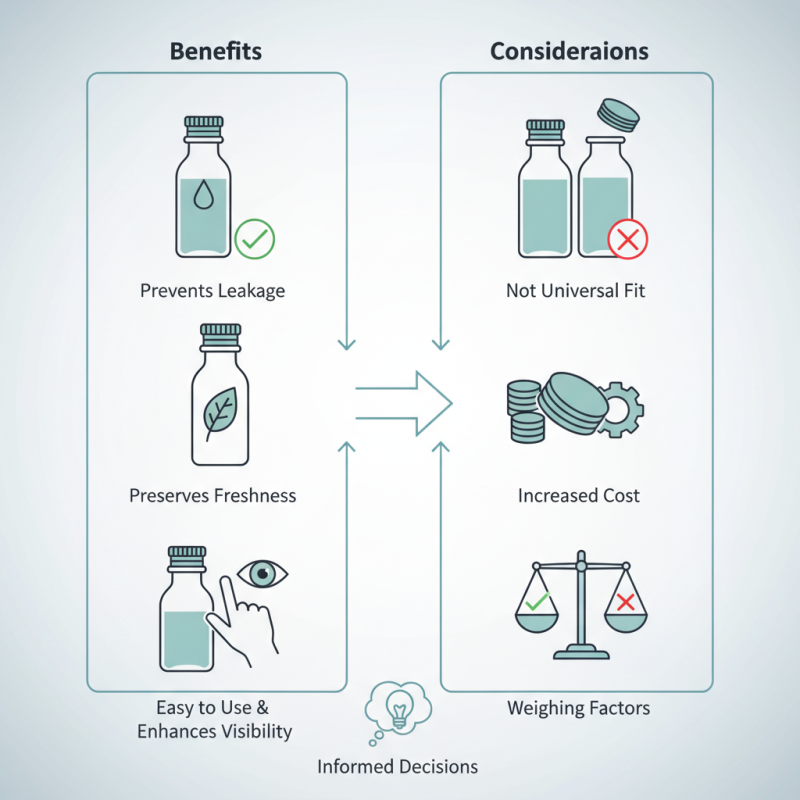

The benefits of using a Custom Glass Bottle Screw Lid are significant. They prevent leakage and preserve freshness. Additionally, these lids are easy to use and enhance product visibility. Consumers appreciate unique packaging that reflects quality.

However, not all designs are perfect. Some lids might not fit every bottle style. Additionally, customization can increase costs. It’s essential to weigh these factors carefully. Exploring the advantages and setbacks of Custom Glass Bottle Screw Lids will help brands make informed decisions. This balance can ultimately lead to better packaging choices in a competitive market.

Definition of Custom Glass Bottle Screw Lid

A custom glass bottle screw lid is designed to fit specific glass containers. It often features a unique shape or color, setting it apart from standard lids. Typically, these lids offer a tight seal, ensuring the contents remain fresh and protected. The customization process allows for branding and personalization, appealing to businesses and individuals alike.

When choosing a custom screw lid, consider the material quality. Glass lids can also be paired with different sealing materials for better functionality. A strong seal enhances the user experience. Remember, aesthetics matter, too. Custom colors or engravings can attract customers.

Tip: Always test samples before making bulk orders. This helps identify any fit issues. Additionally, think about the production timeline. Some custom designs may take longer to produce. Evaluating these aspects saves time and avoids frustration. Also, keep sustainability in mind. Using eco-friendly materials can enhance your brand’s image.

Types of Materials Used in Custom Glass Bottle Screw Lids

Custom glass bottle screw lids are gaining popularity in various industries, especially in food and beverage packaging. The choice of materials used in these lids plays a critical role in functionality and safety. Common materials include polypropylene (PP), glass, and silicone. Each material has its unique benefits and drawbacks.

Polypropylene is often favored for its excellent chemical resistance and lightweight properties. According to a recent industry report, around 45% of screw lids produced are made from PP. This material is affordable yet durable. However, it is not as eco-friendly as glass, raising questions about sustainability. Glass, on the other hand, is highly recyclable and provides an airtight seal. This makes it preferred for many premium products. Nonetheless, the weight of glass can increase shipping costs and is more prone to breakage.

Silicone lids offer a flexible alternative. They are often used in specialized applications where temperature resistance is essential. Their adaptability can be advantageous yet raises inquiries about long-term durability. As industries shift towards more sustainable options, the balance between materials becomes critical. The choice of screw lid material can significantly impact product quality, brand perception, and environmental footprint.

Advantages of Using Custom Glass Bottle Screw Lids

Custom glass bottle screw lids offer numerous advantages for packaging. They provide an airtight seal, which keeps products fresh longer. This is particularly crucial for beverages and food items. According to industry reports, about 70% of consumers prefer glass packaging due to its non-reactive properties. Glass maintains the quality of contents without leaching harmful chemicals, unlike some plastics.

Moreover, the aesthetic appeal of custom glass bottle screw lids cannot be ignored. They provide a premium feel, appealing to eco-conscious consumers. A study revealed that over 60% of consumers are willing to pay more for sustainable packaging. However, the production process can be costly and time-consuming, which may deter some businesses.

While custom glass lids offer great benefits, there are challenges. They are heavier than plastic lids, increasing shipping costs. Additionally, breaking risk during handling may cause losses. Balancing sustainability and practicality remains a critical consideration for businesses aiming to attract consumers while managing costs.

Applications of Custom Glass Bottle Screw Lids in Various Industries

Custom glass bottle screw lids have a wide range of applications across different industries. In food and beverage, these lids ensure airtight seals for items like juices, sauces, and oils. This helps maintain freshness. In pharmaceuticals, they protect sensitive liquids. The lids prevent contamination. Their use is common for essential oils too, offering a secure closure that ensures quality preservation.

Tips: Always choose the right size when selecting lids. A snug fit is essential for preventing leaks. Consider the material of the screw lid; it should match your bottle for optimal results.

In the cosmetic industry, custom glass bottle screw lids cater to various products. They add a touch of elegance to skincare oils and perfumes. The visual appeal can attract customers. However, not all designs work seamlessly. It's important to ensure functionality alongside aesthetics. Rethink designs if they compromise usability.

Tips: Test your lids before mass production. Ensure they open and close smoothly. Pay attention to the user experience. It matters more than you might think.

Considerations for Choosing Custom Glass Bottle Screw Lids

When choosing custom glass bottle screw lids, several key considerations arise. The first is material quality. A study by the Glass Packaging Institute indicates that high-grade glass can enhance product shelf life. This is crucial for preserving the integrity of beverages and other consumables. Poor quality glass can lead to breakage and affect the user experience.

Next, the design of the screw lid must be practical. Effective sealing prevents leakage and contamination. According to data from the Food & Beverage Packaging Association, around 30% of packaging failures involve improper sealing methods. This failure can cause significant loss of products. Ensuring that the lid fits securely with the bottle is vital.

Size and ease of use are also important. Many users prefer lids that are easy to open yet provide a secure seal. A user survey showed that 45% of consumers value convenience when selecting packaged goods. Design flaws can deter customers. Always consider the end-user when selecting a custom lid. Balancing aesthetics with functionality is often challenging but necessary for success.

What is Custom Glass Bottle Screw Lid and Its Benefits? - Considerations for Choosing Custom Glass Bottle Screw Lids

| Feature | Description | Benefits |

|---|---|---|

| Material | High-quality glass | Durable and eco-friendly |

| Closure Type | Screw lid | Ensures tight sealing and prevents leakage |

| Customization Options | Colors, logos, sizes | Enhances brand visibility and appeal |

| Size Variability | Various sizes available | Suitable for different volumes of product |

| Reusability | Washable and refillable | Promotes sustainability and cost-effectiveness |

Skip to content

Skip to content