How to Choose the Best Ball Screw for Sale Guide?

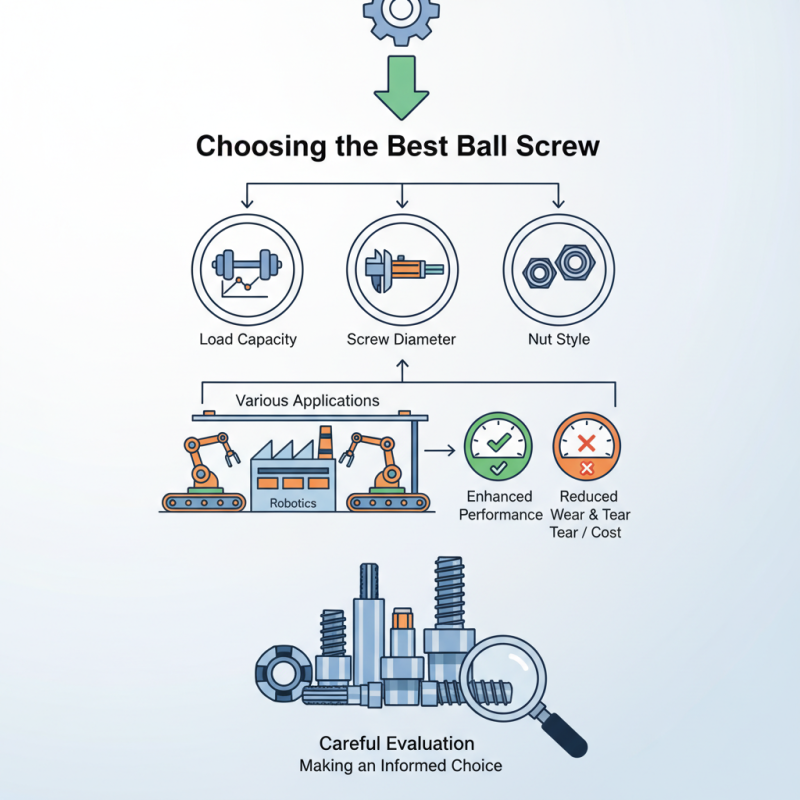

Choosing the right ball screw for sale is crucial for your machinery's efficiency. According to industry expert Dr. James Collins, "Selecting the right ball screw can enhance performance and reduce costs." His insight highlights the importance of making an informed choice in this vital component.

Ball screws play a significant role in various applications, from automation to robotics. These components convert rotary motion into linear motion with precision. However, not all ball screws are created equal. Some may not meet specific load or speed requirements. This can lead to performance issues and increased wear and tear.

When searching for ball screws for sale, consider factors like load capacity, screw diameter, and nut style. Each application may demand different specifications. A mismatch in these aspects can result in unexpected failures. Therefore, carefully evaluating options is essential for long-term success in your projects.

Understanding Ball Screws: Types and Specifications

When considering ball screws, it's essential to understand the various types available. There are several categories, including precision ball screws and ground ball screws. Precision ball screws offer tight tolerances, making them ideal for applications needing exact movements. Ground ball screws are often more affordable. However, they may not provide the same level of accuracy.

Another critical aspect is the specifications of each ball screw. Factors like load capacity, screw diameter, and lead must be evaluated. A higher load capacity is vital for heavy-duty tasks. A larger screw diameter contributes to durability. But there's a trade-off when choosing these specifications. Increasing diameter may limit space in your design.

Choosing the right ball screw can be challenging. One might overlook the importance of linear speed. It's easy to focus only on load and accuracy while neglecting other aspects. Understanding the specific requirements of your application is necessary to make informed decisions. Rushing into a purchase without comprehensive analysis can lead to inefficiencies.

Ball Screw Types and Their Load Capacity

This bar chart displays the load capacity of various ball screw types. The values indicate the maximum load each screw can handle, helping you choose the best option based on your specific application needs.

Key Factors in Selecting Ball Screws: Load Capacity and Accuracy

Choosing the right ball screw involves understanding crucial factors like load capacity and accuracy. Load capacity refers to how much weight the ball screw can handle during operation. If a ball screw is underloaded, it may not perform efficiently. Conversely, overloading can lead to premature failure. Selecting the appropriate load capacity ensures longevity and reliability in your application.

Accuracy is also vital. It defines how precisely the ball screw can position and move your machinery. High precision is critical in applications requiring tight tolerances. However, high accuracy often comes at a higher cost. Balancing between cost and precision can be challenging. Consider how much accuracy your application genuinely needs.

Sometimes, misunderstandings arise regarding these specifications. Users may focus solely on load capacity and overlook accuracy. Alternatively, they may prioritize accuracy without considering if the load capacity is adequate. It's essential to reflect on your project's specific needs. Taking the time to evaluate these factors will lead to better performance. Make informed decisions to avoid unexpected issues later.

Material Considerations for Durability in Ball Screw Application

When choosing a ball screw, material plays a crucial role in durability. The most common materials are steel and stainless steel. Steel offers strength but can rust if exposed to moisture. Stainless steel, while more resistant, may lack the same load-bearing capacity. It’s a balance of performance and environment. These factors dictate the longevity and efficiency of the ball screw.

In high-precision applications, tolerance levels matter. Poorly chosen materials can lead to wear and tear. Hence, it is vital to evaluate the load conditions. Will it be subjected to high forces? Is it in a corrosive environment? These questions must be answered. Not all materials will stand the test of time. Some might need replacing sooner than expected.

Furthermore, surface treatment influences the performance of a ball screw. Coatings can enhance corrosion resistance. However, there can be trade-offs. Some treatments might impact the friction or load capacity. A careful selection process is necessary. Assessing both the environment and the application will guide your choice. Consider these details to ensure that your ball screw performs optimally.

How to Choose the Best Ball Screw for Sale Guide? - Material Considerations for Durability in Ball Screw Application

| Material | Strength | Corrosion Resistance | Weight | Cost | Applications |

|---|---|---|---|---|---|

| Carbon Steel | High | Low | Moderate | Low | General Machinery |

| Stainless Steel | High | Very High | Heavy | Medium | Food Processing & Medical |

| Aluminum | Moderate | Moderate | Lightweight | Medium | Aerospace & Automotive |

| Brass | Moderate | Moderate | Moderate | High | Electrical Applications |

Essential Dimensions: Lead, Diameter, and Thread Pitch Explained

When choosing a ball screw, essential dimensions play a crucial role. Lead refers to the distance a nut moves with one complete screw rotation. It directly affects the speed and efficiency of motion. Typical leads range from 5 mm to 50 mm. According to industry reports, a larger lead can increase speed but may sacrifice axial load capacity, leading to potential performance issues.

Diameter is another critical dimension. A larger diameter provides better load distribution and stability. Most ball screws have diameters from 10 mm to 100 mm. It's common for engineers to select a diameter based on space constraints. However, this may limit the performance under heavy loads. Finding the right balance is essential, yet it can be challenging.

Thread pitch, the distance between threads, influences the screw's precision. A finer pitch allows for higher accuracy but can increase friction. Reports indicate that standard thread pitches vary from 1 mm to 10 mm. Selecting the wrong pitch could lead to inefficiencies or mechanical failures. This intricate relationship among lead, diameter, and thread pitch must be carefully considered. Overlooking one dimension might result in subpar performance.

Comparing Cost vs. Performance: Finding the Best Value in Ball Screws

When selecting the best ball screw, consider both cost and performance. Achieving this balance can be tricky. Some users prioritize low costs, yet they may overlook quality. A cheaper option might fail too soon. This could lead to more expenses down the line.

Performance is vital in ball screws. Examine factors like load capacity and speed. A high-performance screw often costs more upfront. But, if it lasts longer, the total cost may be lower. Look for materials used in the screw. High-quality materials may cost more initially, but they provide better durability.

Each application is unique, and needs vary. You might need a different screw type for a robotic arm versus a CNC machine. Understand your requirements before making a choice. Avoid rushing the decision. Take time to assess various options. Reflect on past purchases to avoid repeating mistakes. Finding the best value in ball screws requires careful consideration and research.

Skip to content

Skip to content