2026 How to Choose Stainless Steel Woven Wire Mesh for Your Needs?

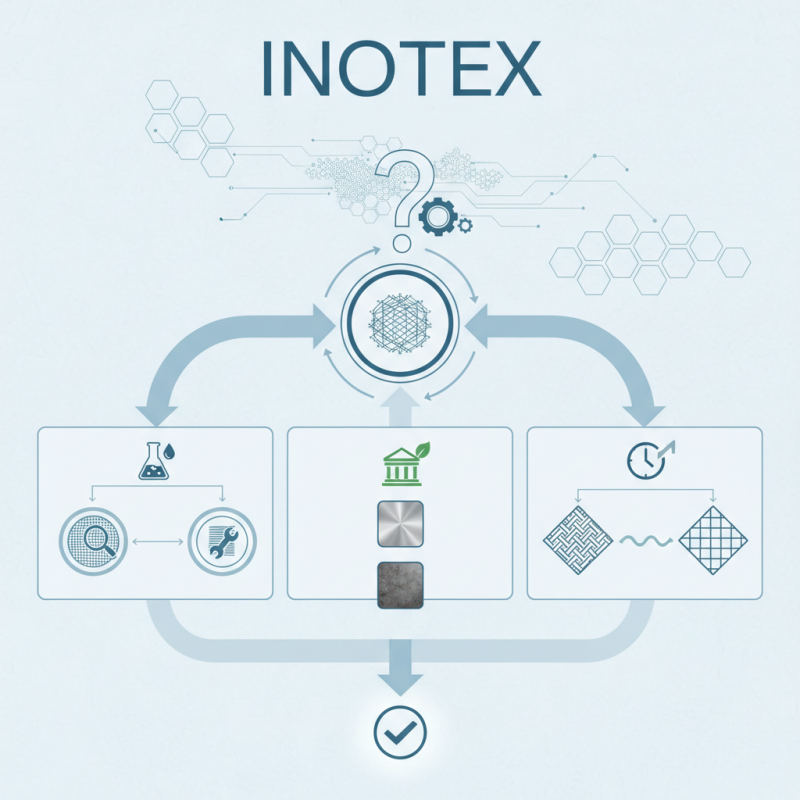

Choosing the right stainless steel woven wire mesh can be a daunting task. According to industry expert John Smith, “Consider your specific requirements before selecting stainless steel woven wire mesh.” This advice emphasizes the importance of understanding your needs fully.

stainless steel woven wire mesh is widely used across various industries. It serves numerous purposes, from filtration to architectural applications. Yet, many people overlook critical factors during selection. For instance, mesh size and wire diameter both significantly affect performance and durability.

The variety within stainless steel woven wire mesh can be confusing. Different grades, weaving types, and finishes present unique challenges. Reflection on these elements is vital to ensure optimal use. Making a decision should involve careful evaluation of one's specific applications and long-term goals.

Factors to Consider When Choosing Stainless Steel Woven Wire Mesh

When selecting stainless steel woven wire mesh, several factors should be prioritized. The choice of wire diameter is crucial. Thicker wires typically offer greater strength but may reduce flexibility. A study by the Stainless Steel World Conference highlights that the optimal wire diameter can significantly impact mesh performance in various applications.

The mesh opening size is another key consideration. Smaller openings provide better filtration but can restrict airflow and reduce strength. According to industry reports, balancing these aspects is essential for effective applications in construction and industrial settings.

Moreover, the type of stainless steel alloy plays a pivotal role. Certain alloys resist corrosion better, while others may be more cost-effective. It’s essential to assess the specific environment where the mesh will be used. This reflection on the alloy choice can be overlooked during the selection process, leading to potential long-term problems. Consideration of these factors ensures that the selected mesh aligns with both durability and functional performance.

Types of Stainless Steel Woven Wire Mesh and Their Applications

When selecting stainless steel woven wire mesh, understanding its types is crucial. One common type is plain weave mesh. It features a simple over-under pattern. This design provides excellent support and is suitable for filtration applications. It’s often used in food processing and chemical industries.

Another popular option is twill weave mesh. This type enhances flexibility and strength. It has a more complex weaving pattern, which allows for larger openings. Twill weave is ideal for applications requiring high flow rates. It's structurally sound and perfect for architectural projects as well.

For more specialized needs, consider micro-mesh. Its fine openings are essential for precise filtration. However, its use can come with challenges, such as clogging. Regular maintenance is necessary to ensure consistent performance. Reflect on your specific needs and environment before making a final choice. Balancing durability and functionality is key.

Stainless Steel Woven Wire Mesh Applications

Understanding Wire Diameter and Mesh Size in Stainless Steel Mesh

When selecting stainless steel woven wire mesh, understanding wire diameter and mesh size is crucial. Wire diameter affects strength and flexibility. A thicker wire provides better tensile strength but may reduce flexibility. For instance, a mesh with a 0.5 mm diameter can withstand higher loads than one with a 0.3 mm diameter. According to industry data, a wire diameter increase of just 0.1 mm can enhance load capacity by up to 25%.

Mesh size also plays a significant role. It refers to the number of openings per linear inch. A mesh size of 80 means there are 80 openings within one inch. Smaller openings are ideal for filtration, while larger ones are suited for ventilation. A study found that meshes with smaller openings can capture particles as small as 74 microns. This specificity can affect applications ranging from agriculture to industrial uses.

Choosing the correct combination of wire diameter and mesh size requires careful consideration of your specific needs. Take time to evaluate how the size will impact your application. It's easy to overlook how these details can affect performance. However, simplifying decisions by focusing solely on one factor can lead to suboptimal results. Take a moment to reflect on how the chosen specifications will meet both immediate and future requirements.

Key Properties of Stainless Steel for Woven Wire Mesh Selection

When selecting stainless steel woven wire mesh, understanding its key properties is crucial. Stainless steel offers excellent corrosion resistance, making it suitable for various environments. This material can withstand harsh chemicals and moisture. However, not all stainless steels are alike. The grade you choose can significantly impact performance in specific applications.

Another important property is strength. Stainless steel woven wire mesh can provide high tensile strength. It helps maintain its shape and integrity under pressure. Yet, it's essential to consider the wire diameter and mesh opening. A finer mesh might not be suitable for heavy-duty applications, while a coarser one may not filter effectively.

Lastly, think about the application's temperature range. Some stainless steels can handle high temperatures well, while others may lose strength. Evaluate your needs carefully. Understanding these properties will help you make a more informed choice. Reflect on your specific requirements, and don’t hesitate to ask for professional advice if needed.

2026 How to Choose Stainless Steel Woven Wire Mesh for Your Needs?

| Property | Description | Ideal Usage |

|---|---|---|

| Corrosion Resistance | High resistance to rust and corrosion in various environments. | Marine applications, chemical processing. |

| Strength | High tensile strength allows for durable applications. | Construction, industrial screens. |

| Temperature Resistance | Can withstand high temperatures without losing structural integrity. | High-heat environments, furnaces. |

| Weldability | Easy to weld, making it suitable for complex designs. | Custom fabrications, architectural designs. |

| Aesthetic Appeal | Sleek, modern look that is easy to maintain. | Decorative applications, facades. |

| Versatility | Can be used in a wide variety of applications. | Food processing, filtration systems. |

Maintenance Tips for Stainless Steel Woven Wire Mesh Longevity

When it comes to stainless steel woven wire mesh, proper maintenance plays a critical role in ensuring its longevity. A recent industry report suggests that up to 30% of mesh failures stem from inadequate care. Regular cleaning helps prevent rust and wear, extending the mesh's lifespan significantly.

Tips:

- Clean your mesh every few months. Use a soft brush and mild detergent.

- Inspect for signs of corrosion. Address issues immediately.

- Store unused mesh in a dry, climate-controlled area.

Environmental factors also contribute to the durability of stainless steel mesh. For example, high humidity can accelerate rust formation, even in stainless steel. A 2021 study indicated that environments with excessive moisture lead to an increase in maintenance requirements by nearly 40%.

Tip:

- Apply a protective coating when necessary. This can create a barrier against corrosion.

- Consider the surrounding conditions before installation. Different settings may require different maintenance strategies.

Choosing the right mesh type is vital, but maintaining it is equally important. Without proper care, even high-quality products can degrade over time. Stay proactive with your maintenance to get the most out of your investment.

Skip to content

Skip to content